Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Oprindelsessted:

Zhejiang, Kina

Mærke navn:

ZK

Ansøgningsfelt:

EV navmotor osv.

Materiale:

Sintret NdFeB

Magnetiseringsretning:

Gennem tykkelse eller tilpasset

PM form:

Rektangulær/blok, ring, bue/segment eller tilpasset

MOQ:

1K eller tilpasset, prisen varierer baseret på ordremængde

Prøvegebyr:

Skal diskuteres

Produktions ledetid:

15-20 dage efter modtaget betaling og ordreoplysninger bekræftet af begge parter

+86-15857968349

+86-15857968349

Elektriske køretøjsteknologier (EV) vokser hurtigt og bliver mere almindelige på markeder over hele verden, hvor Indien er et sådant marked, der er særligt klar til vækst i de kommende år. Denne artikel vil udforske anvendelsesområderne og markedstendenserne for elektriske køretøjers hjulnavmotormagneter på det indiske marked og fremhæve de fordele, som Zhejiang Zhongke Magnetic Industry Co.,Ltd. har ved fremstilling af disse komponenter.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

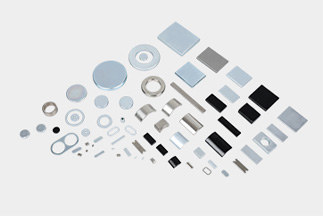

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

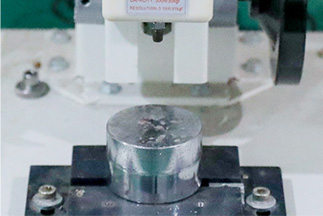

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Brugen af elektriske køretøjs hjulnavmotormagneter stiger hurtigt i Indien, hvor regeringen har sat ambitiøse mål for at reducere kulstofemissioner og luftforurening. Især elbiler fremmes i den offentlige transportsektor, med initiativer som FAME (Faster Adoption and Manufacturing of Hybrid and Electric Vehicles)-ordningen, der tilbyder subsidier og incitamenter til fabrikanter, samt øgede investeringer i elbusser og andre offentlige transportkøretøjer.

Derudover er elektriske tohjulede biler også ved at blive populære i Indien på grund af deres overkommelighed og lave driftsomkostninger. Den stigende efterspørgsel efter disse køretøjer har skabt muligheder for producenter af komponenter såsom hjulnavsmotorer og magneter.

Det indiske elbilsmarked forventes at vokse i et betydeligt tempo i de kommende år med en forventet CAGR på 43,13% fra 2021 til 2026, ifølge en rapport fra Mordor Intelligence. Rapporten fremhæver også, at elektriske tohjulede biler forventes at være det største segment af det indiske el-marked på grund af deres overkommelighed og regeringens fremstød for elektrificering i tohjulssegmentet.

Desuden har den indiske regering sat ambitiøse mål for indførelse af elektriske køretøjer, der sigter mod, at 30 % af alle køretøjer skal være elektriske i 2030. Dette mål, kombineret med øget bevidsthed og incitamenter, forventes at drive væksten på elbilmarkedet og skabe nye muligheder for producenter af komponenter som hjulnavsmotorer og magneter.

Da det indiske marked for elektriske køretøjer fortsætter med at vokse, er der flere nøgletrends, der sandsynligvis vil forme fremtiden for hjulnavmotorer og -magneter til elektriske køretøjer. En af de vigtigste tendenser er den stigende brug af sjældne jordarters magneter i disse komponenter. Disse magneter tilbyder overlegne magnetiske egenskaber sammenlignet med traditionelle magneter og er derfor mere effektive og lettere.

En anden vigtig tendens er fokus på bæredygtighed og reduktion af elbilers miljøpåvirkning. Dette omfatter brugen af genbrugsmaterialer i produktionen af komponenter som hjulnavsmotorer og magneter, samt udvikling af mere energieffektive designs.

Zhejiang Zhongke Magnetic Industry Co.,Ltd. er en førende producent af permanente magneter og motorkomponenter, herunder hjulnavmotormagneter til elektriske køretøjer. Virksomheden har flere vigtige fordele på det indiske marked, herunder:

1.En bred vifte af produkter: Zhejiang Zhongke Magnetic Industry Co.,Ltd. har en omfattende produktportefølje, der omfatter forskellige typer sjældne jordarters magneter, fra N-kvalitet til ZH-kvalitet, og former kan være i blok-, ring-, buesegmentform.

2. Avanceret produktionsteknologi: Zhejiang Zhongke Magnetic Industry Co.,Ltd. har et state-of-the-art produktionsanlæg med avanceret udstyr og teknologier, der giver mulighed for præcis fremstilling af komponenter og dybt strategisk samarbejde med det kinesiske videnskabsakademi.

3. Stærk R&D-kapacitet: Zhejiang Zhongke Magnetic Industry Co.,Ltd. har et dedikeret R&D-team, der er fokuseret på at udvikle nye produkter og forbedre eksisterende. Dette giver virksomheden mulighed for at være på forkant med konkurrenterne og levere innovative løsninger til kunderne.

4. Produkter af høj kvalitet: Zhejiang Zhongke Magnetic Industry Co.,Ltd. har et strengt kvalitetskontrolsystem, der sikrer, at alle produkter lever op til internationale kvalitetsstandarder. Dette er med til at skabe tillid hos kunderne og bevare et godt omdømme på markedet.

Det indiske marked for elektriske køretøjer er klar til betydelig vækst i de kommende år, hvilket skaber muligheder for producenter af komponenter såsom hjulnavmotorer og magneter til elektriske køretøjer. Zhejiang Zhongke Magnetic Industry Co.,Ltd. har flere nøglefordele, der gør det muligt at konkurrere på dette marked, herunder en bred vifte af produkter, avanceret produktionsteknologi, stærk F&U-kapacitet og produkter af høj kvalitet. Da markedet fortsætter med at udvikle sig, er det sandsynligt, at Zhejiang Zhongke Magnetic Industry Co.,Ltd. vil spille en stadig vigtigere rolle i at levere komponenter af høj kvalitet til den indiske elbilindustri.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.