Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Neodymium Iron Boron (NdFeB) magneter, også kendt som sjældne jordarters magneter, er meget udbredt i forskellige industrier, herunder akustik. De er kendt for deres exceptionelle magnetiske egenskaber og høje koercitivitet. NdFeB-magneter tilbyder kraftige magnetfelter i små størrelser, hvilket gør dem ideelle til brug i akustiske applikationer, hvor pladsen er begrænset. Denne artikel vil give et overblik over anvendelsen af NdFeB-magneter i akustik, herunder deres form, størrelse, tolerance, ydeevne, belægningskrav og markedsudsigter i Vietnam og Indien. Derudover vil vi analysere fremstillingsfordelene ved Zhejiang Zhongke Magnetic Industry Co., Ltd.

+86-15857968349

+86-15857968349

NdFeB-magneter i akustiske applikationer:

Akustikindustrien anvender NdFeB-magneter i forskellige applikationer, herunder højttalere, mikrofoner, høreapparater og hovedtelefoner. NdFeB-magneter bruges også i lydudstyr og musikinstrumenter. Deres unikke egenskaber, herunder høj magnetisk feltstyrke og høj koercitivitet, gør dem ideelle til mange akustiske applikationer.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

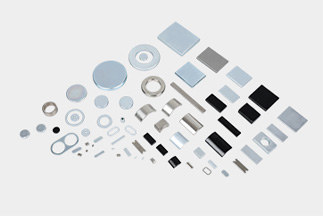

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

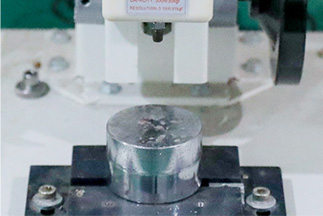

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Form, størrelse og tolerance:

NdFeB-magneter, der anvendes i akustiske applikationer, er tilgængelige i en række former og størrelser, der passer til forskellige krav. Den mest almindeligt anvendte form er en cylindrisk form med en diameter på 3 mm til 40 mm og tykkelse på 1 mm til 30 mm. NdFeB-magneter, der bruges i hovedtelefoner, er normalt små med en diameter på mindre end 10 mm. I mellemtiden bruger højttalere større magneter, normalt med diametre på 10 mm til 40 mm. NdFeB-magneter, der bruges i mikrofoner, er typisk mindre end dem, der bruges i højttalere og har normalt en diameter på 3 mm eller mindre. NdFeB-magneter til akustiske applikationer kræver høje toleranceniveauer for at opfylde specifikke krav, og toleranceniveauet spænder fra /-0,05 mm til /-0,1 mm.

Ydeevne:

NdFeB-magneter, der bruges i akustiske applikationer, skal have fremragende magnetiske egenskaber. Disse omfatter et højt maksimalt energiprodukt, en høj tvangskraft og en høj magnetisk fluxtæthed. Det maksimale energiprodukt for NdFeB-magneter, der anvendes i akustiske applikationer, spænder fra 32MGOe til 55MGOe. Tvangskraften spænder fra 11.000 Oe til 14.000 Oe. Den magnetiske fluxtæthed varierer fra 12.000 G til 15.000 G.

Belægningskrav:

NdFeB-magneter er belagt for at forhindre korrosion, især når de udsættes for fugtige omgivelser. Belægningen giver også et lag af beskyttelse mod skader under håndtering og installation. Almindelige belægningsmaterialer, der bruges til NdFeB-magneter, omfatter nikkel, zink, guld og epoxy. Zink- og nikkelbelægning er de mest almindeligt anvendte på grund af deres lave omkostninger og høje beskyttelsesniveau.

Markedsudsigter i Vietnam og Indien:

Markederne for NdFeB-magneter i Vietnam og Indien har oplevet en stabil vækst gennem årene. De to lande har et betydeligt potentiale i akustikindustrien, og som sådan er der en stigende efterspørgsel efter NdFeB-magneter på disse markeder. I Vietnam er efterspørgslen efter NdFeB-magneter drevet af bilindustrien, hvor de bruges i elbiler, elruder og motorer. Markedet i Indien oplever vækst på grund af den øgede anvendelse af NdFeB-magneter i forbrugerelektronik, rumfart og bilindustrien.

Produktionsfordele ved Zhejiang Zhongke Magnetic Industry Co., Ltd:

Zhejiang Zhongke Magnetic Industry Co., Ltd. er en førende NdFeB-magnetproducent i Kina. Virksomheden har betydelig erfaring med produktion af NdFeB-magneter til forskellige industrier, herunder akustik. Virksomhedens produktionsanlæg er udstyret med moderne faciliteter, herunder avanceret produktionsudstyr, testmaskiner og inspektionsstationer. Ved hjælp af avanceret teknologi producerer virksomheden NdFeB-magneter af høj kvalitet med et højt niveau af præcision og konsistens. Virksomheden har udviklet et strengt kvalitetskontrolsystem, der sikrer en løbende forbedring af produkternes kvalitet. NdFeB-magneterne af høj kvalitet produceret af Zhejiang Zhongke Magnetic Industry Co., Ltd. har opnået tillid fra kunder over hele verden.

NdFeB-magneter har en bred vifte af applikationer i akustikindustrien, herunder højttalere, mikrofoner, høreapparater og hovedtelefoner. Deres unikke egenskaber, herunder høj magnetisk feltstyrke og høj koercitivitet, gør dem ideelle til brug i akustiske applikationer. NdFeB-magneter, der bruges i akustik, kommer i forskellige former, størrelser og toleranceniveauer, og markedsudsigterne i Vietnam og Indien er lovende. Zhejiang Zhongke Magnetic Industry Co., Ltd. tilbyder med sin avancerede teknologi og produktionskapacitet højkvalitets NdFeB-magneter, der opfylder behovene hos kunder i akustikindustrien og videre.3

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.